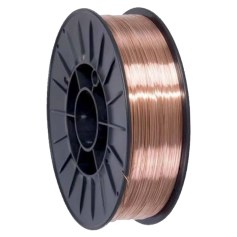

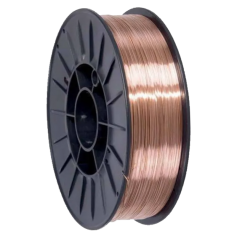

Product: YAWATA 71T-1 Flux Cored Arc Welding Wires (FCAW)

Classification:

AWS A5.20: E71T-1

JIS Z3313: YFW-C50DR

Description:

The YAWATA 71T-1 is a flux cored arc welding wire designed to be used with CO₂ shield gas. It is known for its smooth running, very low spatter, and easy slag removal, which results in excellent X-ray quality welds. It is recommended for high-speed fillet and butt welding of mild and medium-strength steel.

Applications:

This wire is suitable for all-position welding of mild and medium-strength steel used in various applications, including:

Machinery

Structures

Ships

Bridges

Towers

Chemical engineering apparatus

Storage tanks

Typical Chemical Composition of Deposited Metal:

C: 0.05%

Si: 0.51%

Mn: 1.26%

P: 0.010%

S: 0.008%

Typical Mechanical Properties of Deposited Metal:

Tensile Strength: 570 N/mm² (82,700 psi)

Yield Strength: 510 N/mm² (74,000 psi)

Elongation: 29%

Charpy V-Notch (at -18°C): 100 J (9.8 kgf·m)

Sizes & Recommended Current Range (AC or DC ±):

Diameter: 1.2 mm, 1.4 mm, 1.6 mm

Packing Weight: 15 kg

Welding Position: F, HF, H, V-Down

Current (A):

F, HF: 120-300 A (1.2mm), 150-400 A (1.4mm), 180-450 A (1.6mm)

H: 120-280 A (1.2mm), 150-320 A (1.4mm), 180-350 A (1.6mm)

V-Down: 200-260 A (1.2mm), 220-270 A (1.4mm), 230-280 A (1.6mm)

Features:

Soft arc

Low spatter

Beautiful beads

Smooth surface

Low tip wear

1 x BATTERY...RM108.00

1 x BATTERY...RM108.00 1 x KEN...RM269.00

1 x KEN...RM269.00 1 x HEAVY DUTY...RM185.00

1 x HEAVY DUTY...RM185.00 1 x KEN...RM299.00

1 x KEN...RM299.00 1 x MINI AIR...RM17.00

1 x MINI AIR...RM17.00 1 x AIRTAC...RM55.00

1 x AIRTAC...RM55.00 1 x KEN 12V...RM350.00

1 x KEN 12V...RM350.00 1 x KEN...RM109.00

1 x KEN...RM109.00 1 x BOSSMAN...RM12.00

1 x BOSSMAN...RM12.00 1 x MAKITA...RM220.00

1 x MAKITA...RM220.00 1 x KEN...RM299.00

1 x KEN...RM299.00 1 x WOOD HEAD...RM7.00

1 x WOOD HEAD...RM7.00 1 x KEN 20V...RM720.00

1 x KEN 20V...RM720.00

_result.jpg)

.png)

.png)

INVERTER TIG WELDING MACHINE CW ASSY SWTIG200S (6).jpg)